Automatic Line Stop

自動停止·jidō teishi·"automatic stop"

Personalize This

Get insights for your role

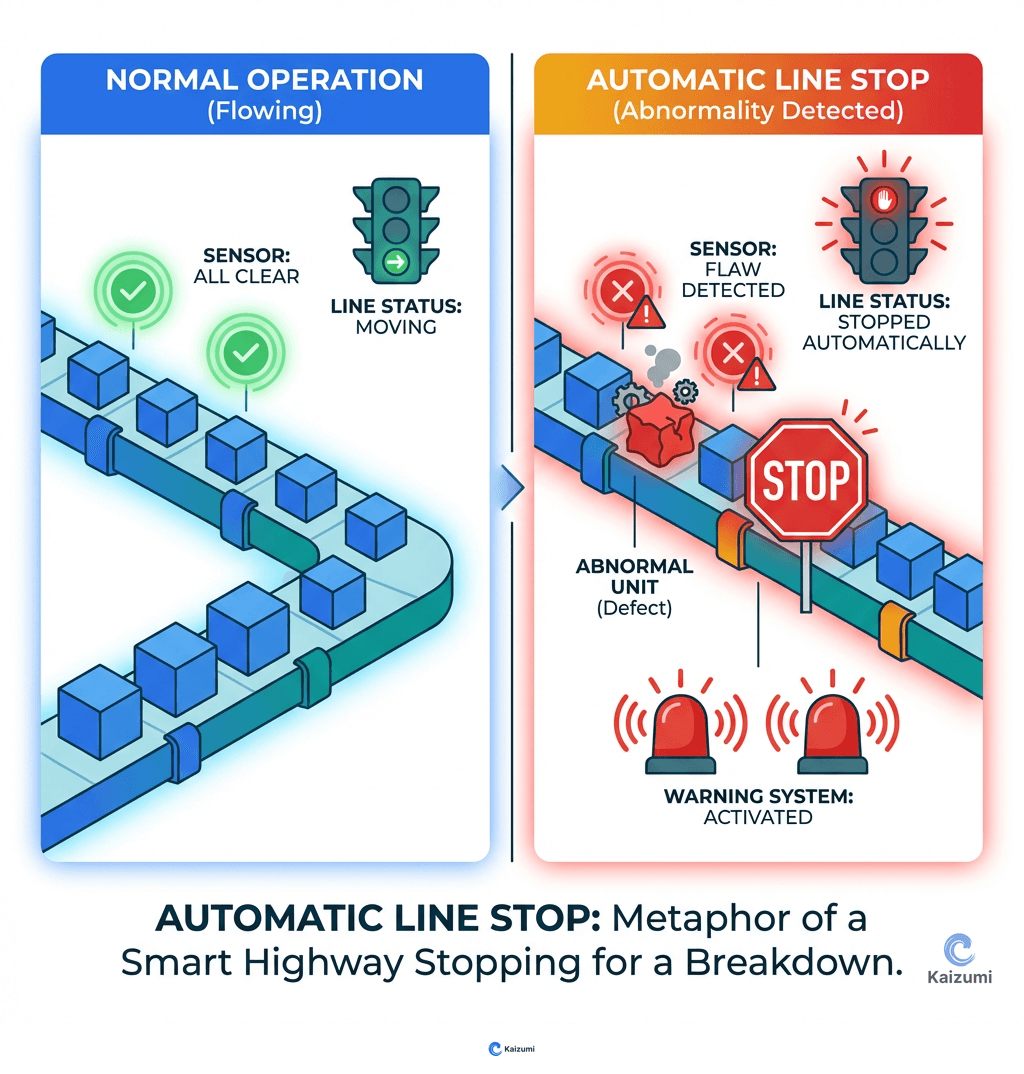

Automatic line stop is a mechanism that halts production immediately when an abnormality is detected, preventing defects from moving downstream.

Definition

Automatic line stop is a built-in mechanism that halts production immediately when a machine or process detects an abnormal condition—a quality defect, equipment malfunction, or missing component. Rather than continuing to produce defects, the system stops and signals for help. This is a core element of jidoka (autonomation): machines are given the "intelligence" to detect problems and stop themselves. Automatic line stop prevents defects from flowing downstream where they become more expensive to fix and harder to trace to their root cause.

Examples

An automotive assembly line has sensors at each station that detect missing components. If a car body arrives without a bracket that should have been installed upstream, the sensor triggers an automatic stop. The line halts, andon lights indicate the problem location, and team leaders investigate before any more vehicles are affected.

Key Points

- Problems are caught at the source, when root cause is still identifiable

- Stopping immediately seems costly but is far cheaper than downstream defects

- Requires rapid response systems to minimize stoppage duration

- Builds quality into the process rather than relying on end-of-line inspection

Common Misconceptions

Line stops hurt productivity. Short-term, yes—long-term, no. Every defect that flows downstream multiplies in cost: rework, scrap, warranty claims, customer dissatisfaction. Stopping immediately minimizes total cost.

Automatic stops can replace human judgment. Automatic stops catch detectable abnormalities, but humans must investigate root causes and implement countermeasures. The stop creates the opportunity; humans must use it.