Chaku-Chaku

着々·chaku-chaku·"load-load"

Personalize This

Get insights for your role

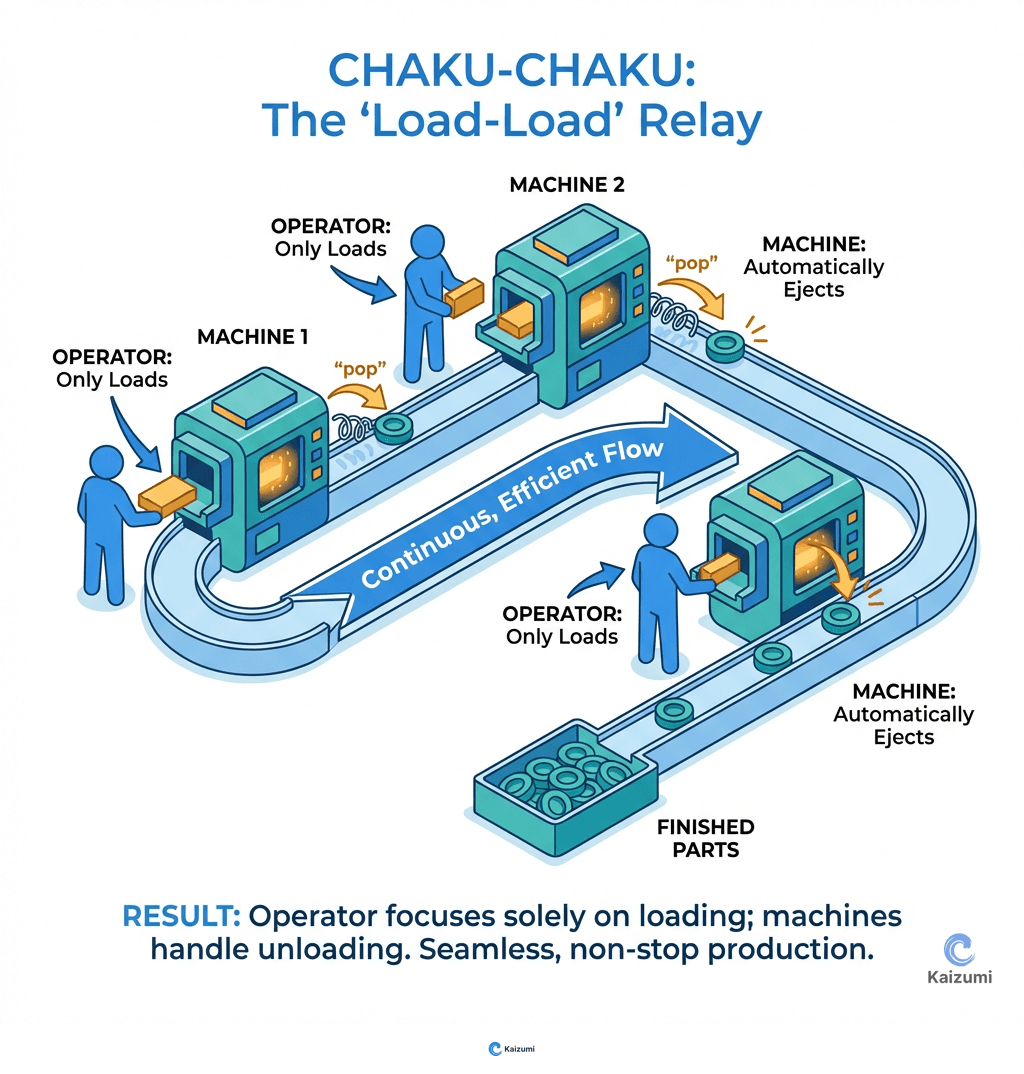

Chaku-chaku is a production method where an operator loads machines in sequence while each machine automatically unloads and cycles.

Definition

Chaku-chaku (literally "load-load") is a production method where an operator walks through a sequence of machines, loading each one while it automatically unloads the previous piece and begins its cycle. The operator's job is simplified to just loading—machines handle unloading, processing, and ejecting parts. This requires machines designed with auto-eject capability and arranged in sequence (typically U-shaped). Chaku-chaku enables one operator to run many machines efficiently while maintaining one-piece flow, as the operator's cycle time is mostly walk time and simple load motions.

Examples

A machining cell has six CNC machines arranged in a U-shape. Each machine automatically ejects finished parts into a chute. The operator walks the cell with a cart of blanks, loading each machine as they pass. By the time they complete the circuit, the first machine is ready for the next piece. One operator produces what previously required six, with faster flow and immediate quality feedback.

Key Points

- Requires machines designed to auto-eject—retrofitting may be needed

- Cell layout must minimize walk distance while maintaining sequence

- Operator cycle time = walk time + load time; must be less than longest machine cycle

- Creates natural pacing and immediate quality feedback

Common Misconceptions

Chaku-chaku requires identical machines. Machines can differ as long as their cycle times are compatible with the operator's circuit time. Faster machines may need wait time built into the sequence.

Any cell can become chaku-chaku. Machines must have auto-unload capability. Machines requiring manual unload, complex quality checks at each station, or highly variable cycle times don't fit the chaku-chaku model.