Cross-Dock

Personalize This

Get insights for your role

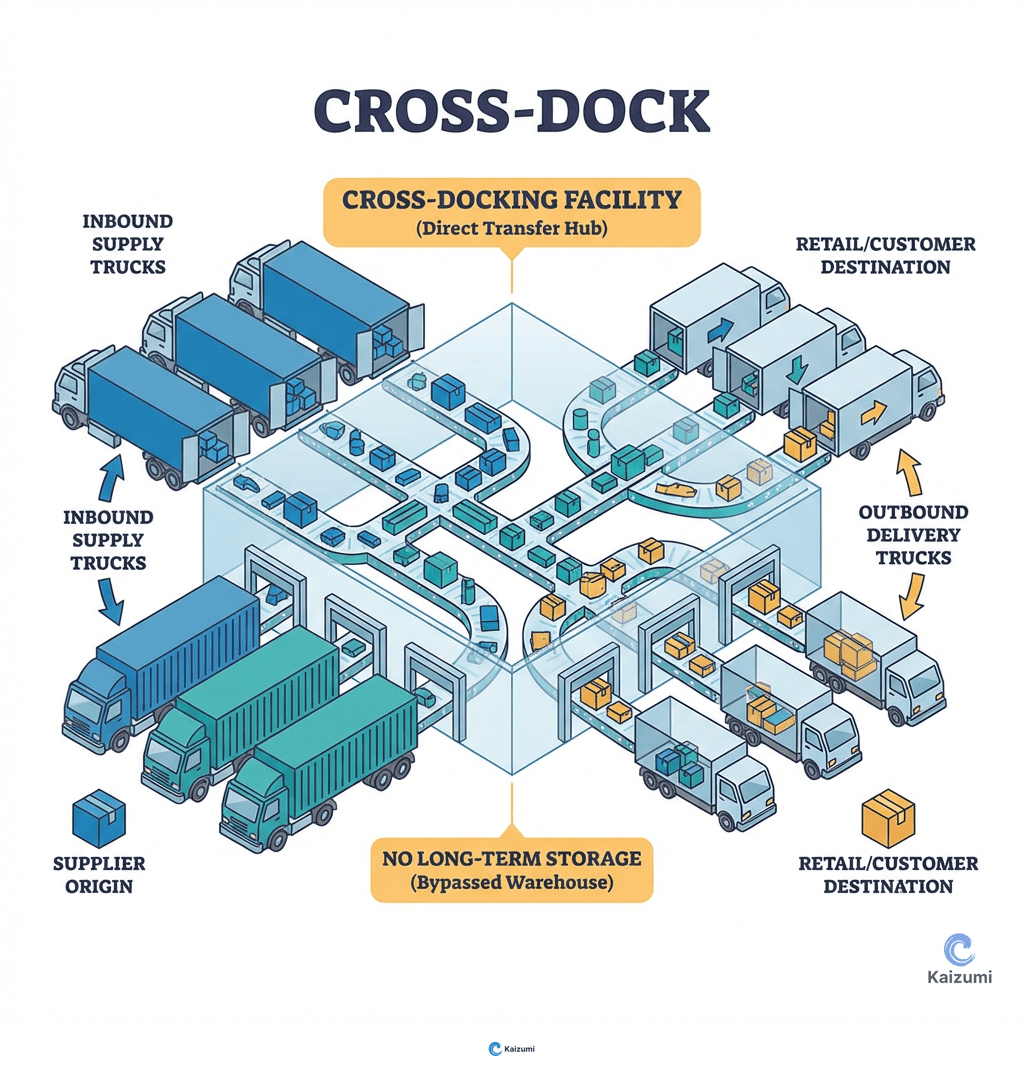

Cross-docking is a logistics practice where incoming materials are transferred directly to outbound shipping with minimal or no storage.

Definition

Cross-docking is a logistics strategy where incoming goods are unloaded from inbound transportation, sorted, and loaded directly onto outbound transportation with minimal or no intermediate storage. Products "cross the dock" from receiving to shipping without entering warehouse inventory. This eliminates storage, retrieval, and the associated handling costs while dramatically reducing lead time. Cross-docking requires precise coordination between suppliers, the cross-dock facility, and customers—arrivals must align with departures, and sorting must happen rapidly.

Examples

An assembly plant receives components from multiple suppliers at a cross-dock facility. Deliveries arrive throughout the day, are sorted by production line and sequence, and are loaded onto milk run trucks that deliver to the plant hourly. Parts never enter warehouse storage—they cross the dock from supplier trucks to plant delivery trucks.

Key Points

- Eliminates storage and associated handling costs

- Requires precise coordination and timing between inbound and outbound

- Best suited for high-volume, predictable, time-sensitive items

- Sorting speed and accuracy are critical success factors

Common Misconceptions

Cross-docking works for all products. Cross-docking requires predictable demand, reliable suppliers, and sufficient volume. Low-volume or highly variable items may need traditional warehousing.

Cross-docking is just fast warehousing. True cross-docking means no storage—items flow directly from inbound to outbound. If items sit even briefly in storage locations, it's not cross-docking.