Finished Goods

Personalize This

Get insights for your role

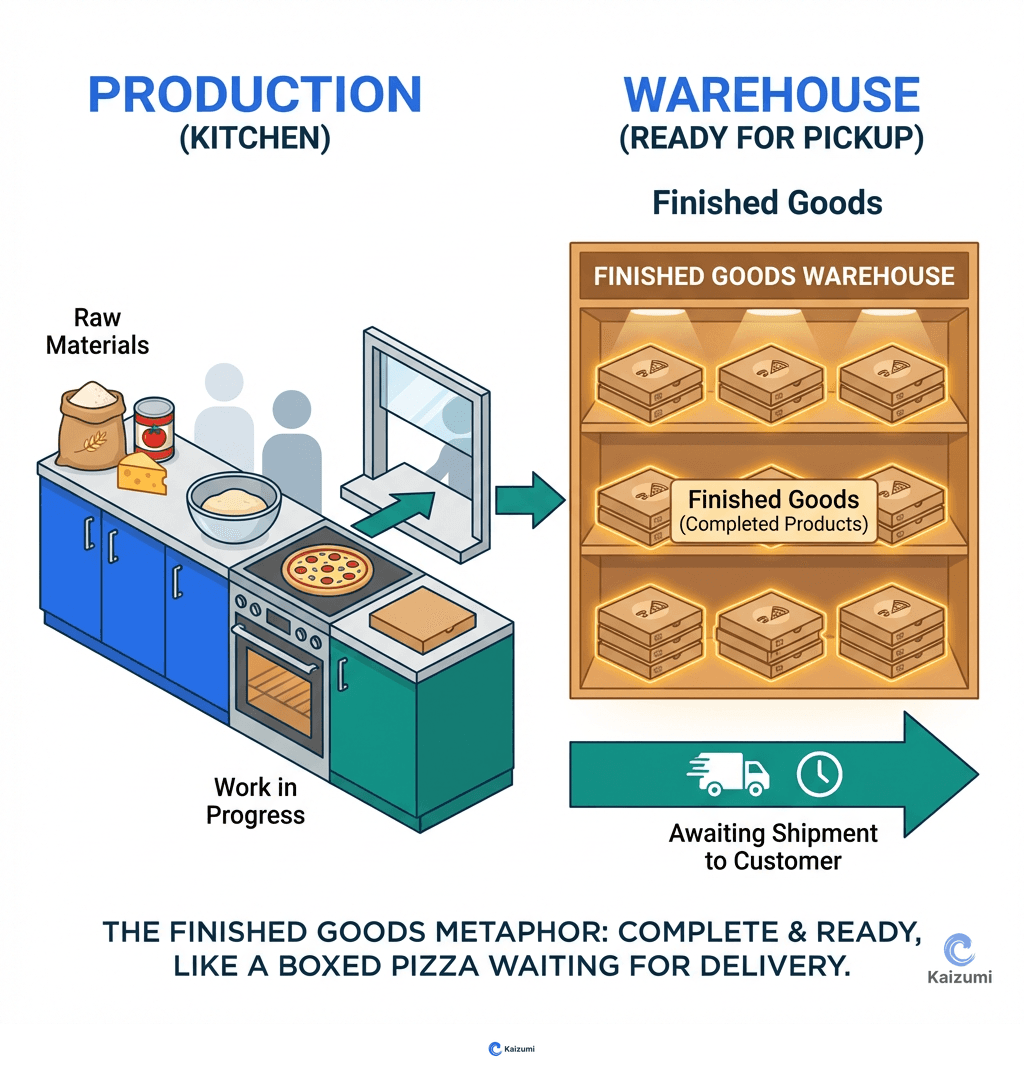

Finished goods are completed products ready for delivery to customers, representing the final inventory stage before sale.

Definition

Finished goods are completed products that have passed final inspection and are ready for delivery to customers. This is the last inventory stage before sale—all manufacturing work is complete, but the customer hasn't yet received the product. Finished goods inventory carries cost (storage, handling, obsolescence risk) but enables rapid response to customer orders. The tension between customer service (more finished goods = faster delivery) and inventory cost (less finished goods = lower carrying cost) is a fundamental trade-off. Lean systems minimize finished goods through short lead times and build-to-order capability.

Examples

An appliance manufacturer holds 2 weeks of finished goods to provide immediate delivery to retailers. This inventory ties up millions in capital and warehouse space. Converting to a 3-day build-to-order model would reduce finished goods by 80% while maintaining service levels—if production flexibility enables it.

Key Points

- Finished goods inventory reflects the gap between lead time and delivery expectation

- Carrying cost includes storage, handling, obsolescence, and capital tied up

- Reducing finished goods requires reducing production lead time

- Build-to-order eliminates finished goods but requires short, reliable lead time

Common Misconceptions

Finished goods inventory equals good customer service. Service comes from the ability to deliver, not from inventory sitting in warehouses. If production can respond quickly, finished goods inventory becomes unnecessary.

Finished goods cost is just storage. Carrying costs include capital cost, obsolescence risk, handling, damage, insurance, and taxes—often 20-30% of inventory value per year.