Shipping Stock

Personalize This

Get insights for your role

Shipping stock is finished goods inventory staged and ready for imminent shipment, positioned near docks or loading areas.

Definition

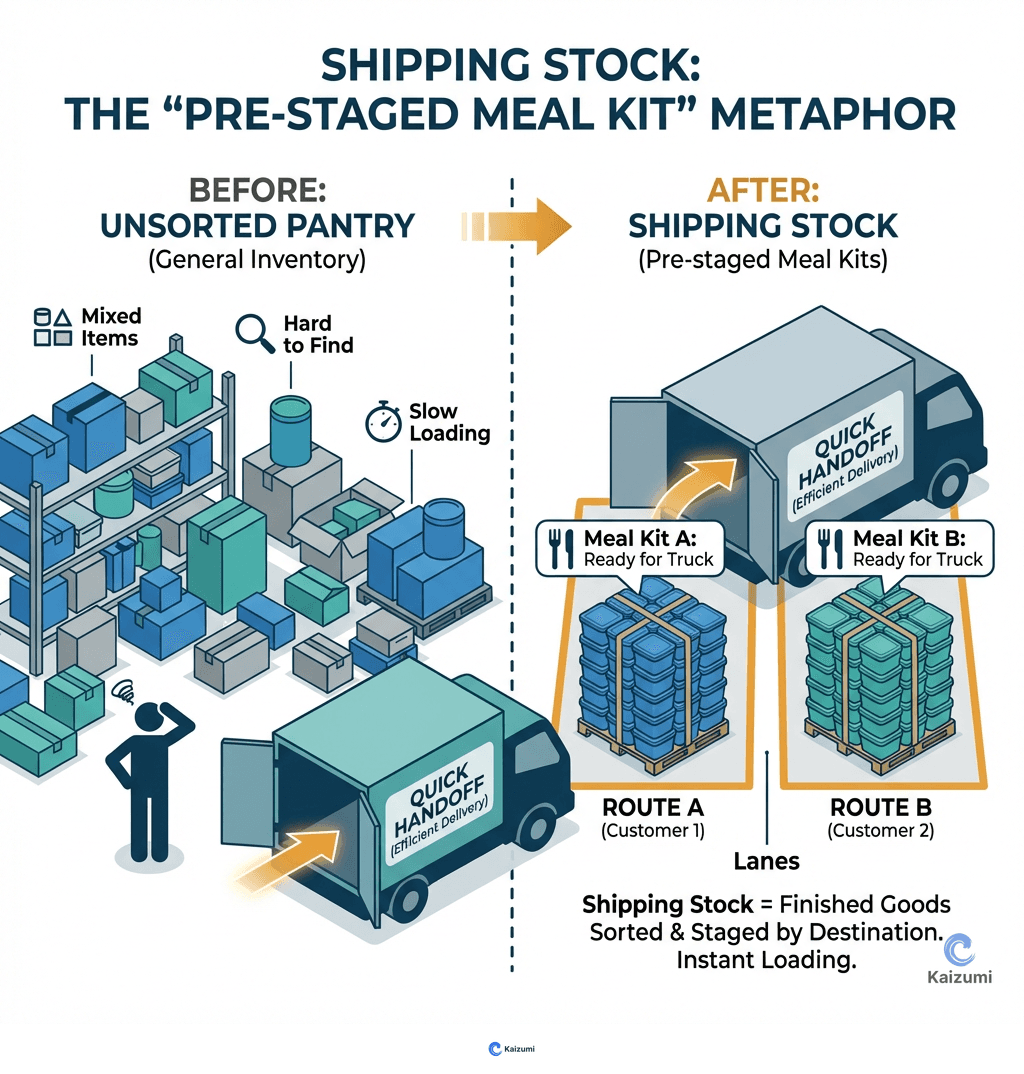

Shipping stock is the subset of finished goods inventory that has been staged for imminent shipment—positioned near shipping docks, sorted by customer or delivery route, and ready for loading. Shipping stock represents the final inventory buffer between production and customer delivery. The amount of shipping stock is determined by shipping frequency and production timing: hourly truck departures require less shipping stock than daily shipments. Lean systems minimize shipping stock by coordinating production completion timing with shipping schedules.

Examples

An automotive supplier ships to customers on a fixed schedule: three trucks daily at 6 AM, 2 PM, and 10 PM. Shipping stock at each departure consists of the previous hours' production staged by customer sequence. Just-in-sequence production means most items go directly from final assembly to shipping stock to truck, minimizing staging time.

Key Points

- Minimized by synchronizing production with shipping schedules

- Should be organized by customer, route, or carrier for efficient loading

- FIFO management prevents old inventory from languishing

- Visual management shows what's staged versus what's expected

Common Misconceptions

Shipping stock is a buffer we can't eliminate. Some coordination time between production and shipping is necessary, but excess shipping stock often reflects poor synchronization rather than necessity.

All finished goods are shipping stock. Only finished goods staged for imminent shipment are shipping stock. Finished goods in a warehouse awaiting orders are general finished goods inventory.