Material Handling

Personalize This

Get insights for your role

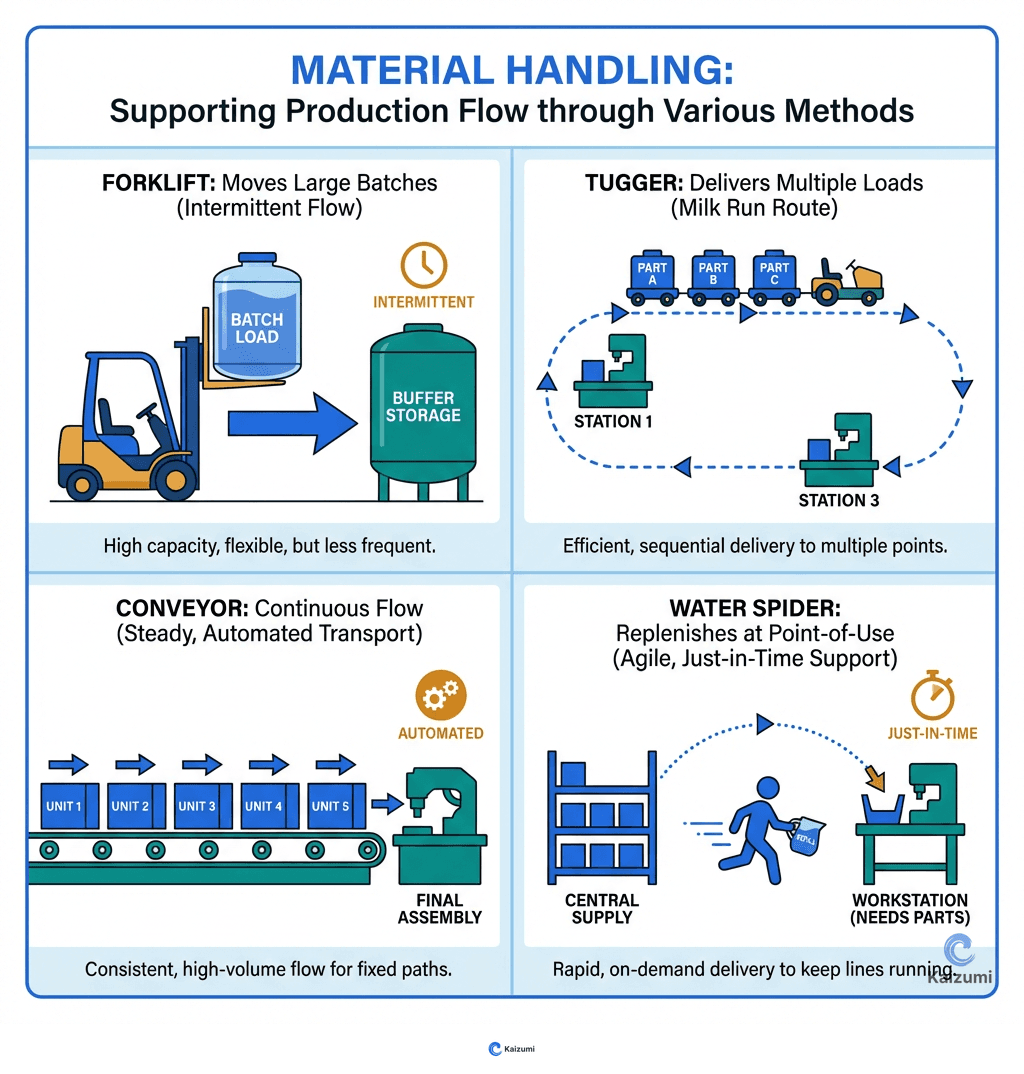

Material handling encompasses all activities involved in moving, storing, protecting, and controlling materials throughout production and distribution.

Definition

Material handling includes all activities involved in moving, storing, protecting, and controlling materials from receiving through shipping. This encompasses equipment (forklifts, conveyors, tuggers), methods (batch delivery, milk runs, water spider), storage systems (racks, flow lanes, point-of-use), and the people who perform these tasks. While material handling is necessary to support production, it is fundamentally non-value-adding—customers don't pay for moving materials around. Lean material handling minimizes handling steps, reduces distances, and delivers materials where and when needed without excess inventory or production disruption.

Examples

A plant converted from forklift batch delivery to tugger-based milk runs. Instead of dropping pallets of parts that operators must then move to their workstations, tuggers deliver small quantities directly to point-of-use every 30 minutes. Handling touches dropped from 5 (receive, putaway, retrieve, deliver, final position) to 2 (receive, deliver to point-of-use).

Key Points

- Handling is necessary but non-value-adding—minimize it

- Right-sized containers reduce handling effort

- Frequent small deliveries beat infrequent large deliveries

- Layout and process design determine handling requirements

Common Misconceptions

Better material handling means bigger forklifts. Bigger equipment moves bigger batches, which is often the opposite of what lean requires. Right-sized handling equipment enables right-sized deliveries.

Automating handling solves the problem. Automation may reduce labor cost but doesn't eliminate the underlying waste. First simplify and improve flow; then consider whether automation adds value.