Process Village

Personalize This

Get insights for your role

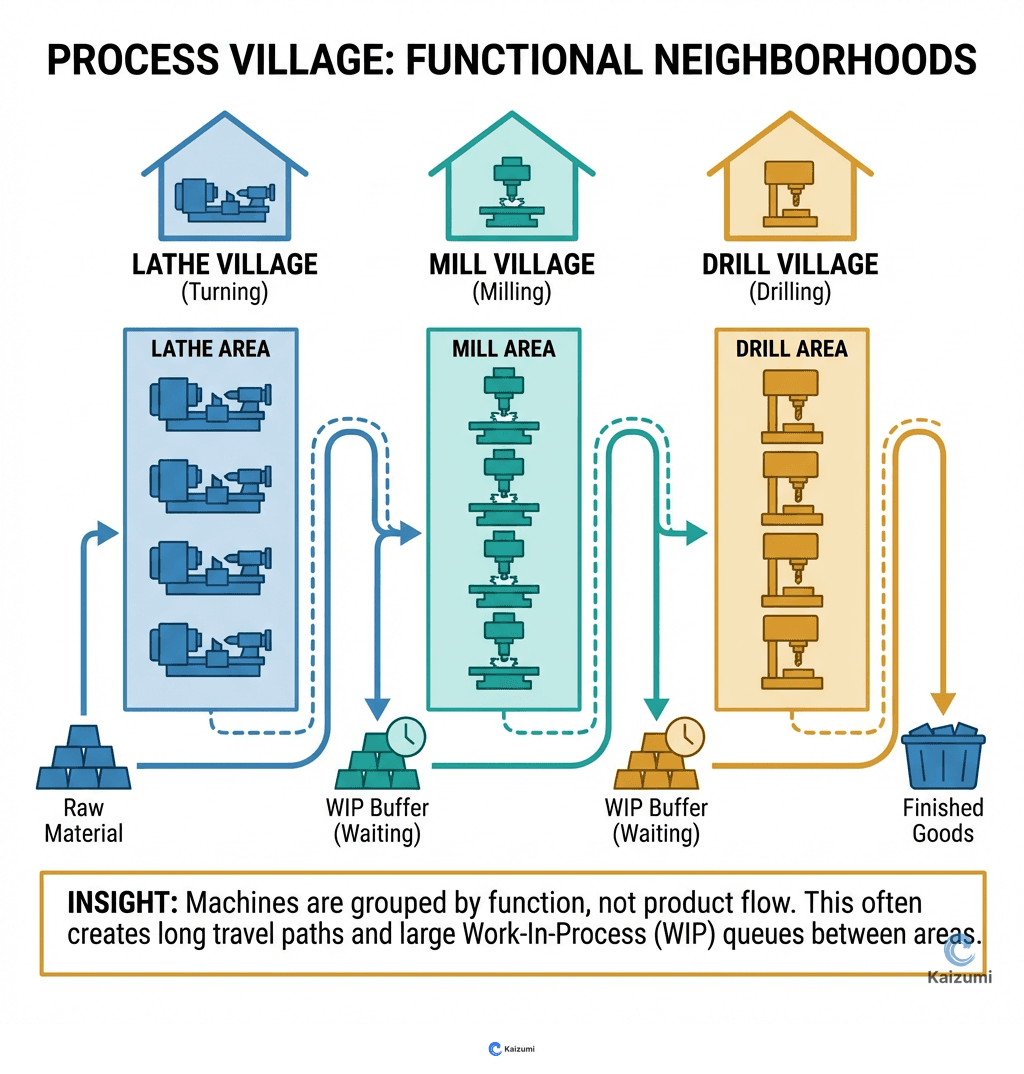

A process village is a traditional layout where similar machines or functions are grouped together, requiring products to travel between villages.

Definition

A process village (or functional layout or job shop layout) is a traditional arrangement where similar machines or functions are grouped together: all lathes in one area, all mills in another, all heat treat in a third. Products travel from village to village for each operation. This layout develops naturally because it simplifies machine supervision, centralizes expertise, and makes capacity visible. However, process villages create batch-and-queue production, long lead times, excessive work-in-process, and complex scheduling. Lean production often transforms process villages into product-focused cells where different machine types are arranged in sequence for a product family.

Examples

A machine shop has the "lathe village," "mill village," "grinding village," and "heat treat village." A part visits each village, waiting in queue at each for batch processing. Lead time: 4 weeks. After conversion to product-focused cells, lead time dropped to 3 days.

Key Points

- Natural development driven by functional specialization

- Creates batch-and-queue production with long lead times

- Makes machine utilization visible but hides system performance

- Lean transformation often converts villages to product-focused cells

Common Misconceptions

Process villages maximize machine utilization. Villages may keep machines busy, but overall system performance suffers. High machine utilization with low flow efficiency is false economy.

Process villages are always wrong. Some operations genuinely require process villages—expensive monuments that serve multiple product lines. The question is whether the village is necessary or merely traditional.